VIEWAPP: Do digital inspections require intelligence?

VIEWAPP digital inspection technology is already an advanced modern system for remote control and monitoring of objects for various industries, processing thousands of inspections per day. When you add the power of artificial intelligence to it, you get a formidable combination capable of recording and analysing data with the highest quality. With the advent of neural capabilities, the processes of protecting and analysing inspection results have become faster, more accurate and more resistant to human error and manipulation.

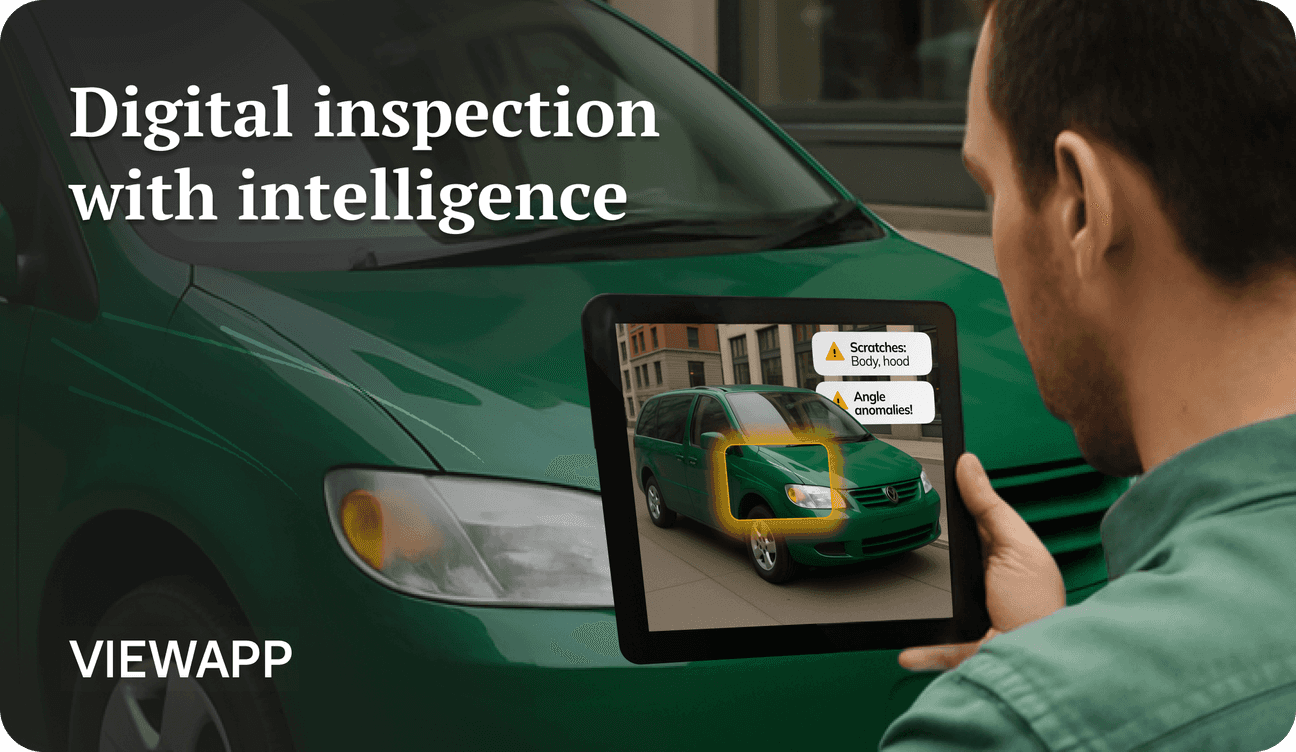

Intelligent algorithms strengthen every link in the chain, fr om quality control of visual materials to alerts to experts about potential risks or discrepancies. During inspection, each object is subjected to cross-analysis using several detectors at once, which ultimately provides a very clear picture of the authenticity of the data obtained, and the expert receives pre-checked and structured material with an emphasis on potentially important areas.

At this stage of technological development, it is not possible to completely replace the expert, but their participation becomes more effective: routine work is transformed fr om a heavy burden into a simple and convenient process of managing inspection results. Instead of endless manual checks, they are able to focus on making decisions wh ere professional assessment is truly important.

The use of neural analysis began with the selective application of several detectors, but this is only the beginning. As data accumulates and models develop, the system gradually learns to see more, interpret complex cases more accurately, and adapt to the specifics of different objects and scenarios.

There is much debate surrounding artificial intelligence about how useful or harmful it is. As for VIEWAPP's digital inspection technology as a leading provider, in today's reality, the integration of neural capabilities is absolutely necessary and is becoming a key factor in improving the quality, reliability, and efficiency of the entire system.

What do companies ultimately get?

- Improved quality and accuracy of analysis. Intelligent tools help to interpret data more deeply, identify even subtle anomalies and increase confidence in the results.

- Faster processing and decision-making. Automating routine checks reduces the workload on experts and allows them to focus on complex or controversial cases.

- Resistance to errors and fraud. Intelligent detectors and multi-level cross-analysis strengthen protection against manipulation.

- Scalability without loss of quality. The system is capable of efficiently processing thousands of inspections daily while maintaining a high level of control.

- Adaptation and training. The intelligent platform is constantly improving, taking into account the specifics of different objects and changing conditions.

Thus, the integration of artificial intelligence into VIEWAPP digital inspections is a natural development of the technological platform, equipping it with the latest intelligent tools.

As a result, the company achieves significant improvements not only in the quality and reliability of processes, but also a tangible increase in business efficiency and profitability.

In an environment wh ere reliability and speed are becoming critical to business, intelligence in digital inspections is not just an advantage, but the basis for competitive superiority. VIEWAPP makes this foundation available today.